Industry News

Overview of Rubber Shock Pad 2

Views : 203

Update time : 2020-04-13 10:02:47

The size of the rubber material loss factor is not only related to the structure of the rubber itself, but also to the temperature and frequency. At normal temperature, natural rubber (NR) and cis-butadiene rubber (BR) have smaller loss factors. Styrene-butadiene rubber (SBR), neoprene (CR), ethylene-propylene rubber (EPR), polyurethane rubber (PU), and silicone rubber The loss factor is in the middle, but butyl rubber (HR) and nitrile rubber (NBR) have the largest loss factors. Rubber materials used for anti-vibration purposes are generally divided into 5 types, namely NR, SBR, BR are ordinary rubber materials; NBR is used for oil-resistant vulcanizates; CR is used for weather-resistant vulcanizates; IIR is used for high-damping vulcanizates; Hot vulcanizate. Although NR has a small loss factor, it has the best overall performance, excellent elasticity, good fatigue resistance, low heat generation, small creep, good adhesion to metal parts, cold resistance, electrical insulation, and processing performance. Therefore, NR is widely used for shock absorption purposes. When low-temperature resistance or weather resistance is required, it can be used in combination with BR or CR or modified by blending. The absorbers made of NR, BR and metal salts containing organic acids containing -OH groups with a carbon number greater than 4 by Nishiue et al. Have better durability and are compressed at 70 ℃ × 22h and 40 ℃ × 148h The permanent deformation is 17.0% and 11.7% respectively.

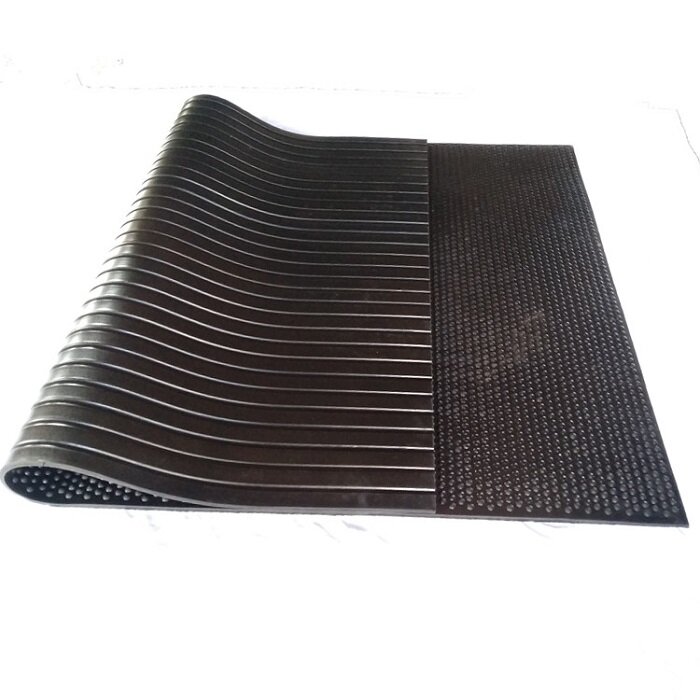

Advantages: 1. Shockproof rubber pad hole-shaped design, strong permeability, easy to drain. Keep the ground clean and dry to prevent the first-line workers from falling, and truly protect the safety of workers. 2. Shockproof rubber pad made of imported high-quality rubber material, durable, long service life, can be used in outdoor sunlight and wet and dark environment. 3. Anti-shock rubber pad anti-fatigue and noise reduction function It is especially suitable for long-term standing front-line workers and service industry personnel, which can effectively reduce the fatigue of personnel and reduce the pressure on the legs and shoulders. 4. The anti-shock rubber pad is light in weight, the general cushion is under 10 kg, easy to clean and carry. Disadvantages: Not resistant to weather and oil (vegetable oil resistant).

Advantages: 1. Shockproof rubber pad hole-shaped design, strong permeability, easy to drain. Keep the ground clean and dry to prevent the first-line workers from falling, and truly protect the safety of workers. 2. Shockproof rubber pad made of imported high-quality rubber material, durable, long service life, can be used in outdoor sunlight and wet and dark environment. 3. Anti-shock rubber pad anti-fatigue and noise reduction function It is especially suitable for long-term standing front-line workers and service industry personnel, which can effectively reduce the fatigue of personnel and reduce the pressure on the legs and shoulders. 4. The anti-shock rubber pad is light in weight, the general cushion is under 10 kg, easy to clean and carry. Disadvantages: Not resistant to weather and oil (vegetable oil resistant).

The anti-vibration rubber has a creep phenomenon, which tends to stabilize after 14 days, so the machine tool is required to adjust the level again after 14 days. When a certain tension is maintained, the deformation of the rubber changes with time. After a period of time, the tension is released, and the recovery of the rubber cannot be completed. There will be some residual deformation. This is the creep characteristic of rubber. Any material has certain creep characteristics, but whether it is obvious. Or can it be expressed within the time scale of observation? For example, some small molecular solid materials such as glass, steel, or stone require creep to be observed on a very long time scale. The unvulcanized rubber will show up on a relatively short time scale. Plastic is between rubber and small molecular solid materials.

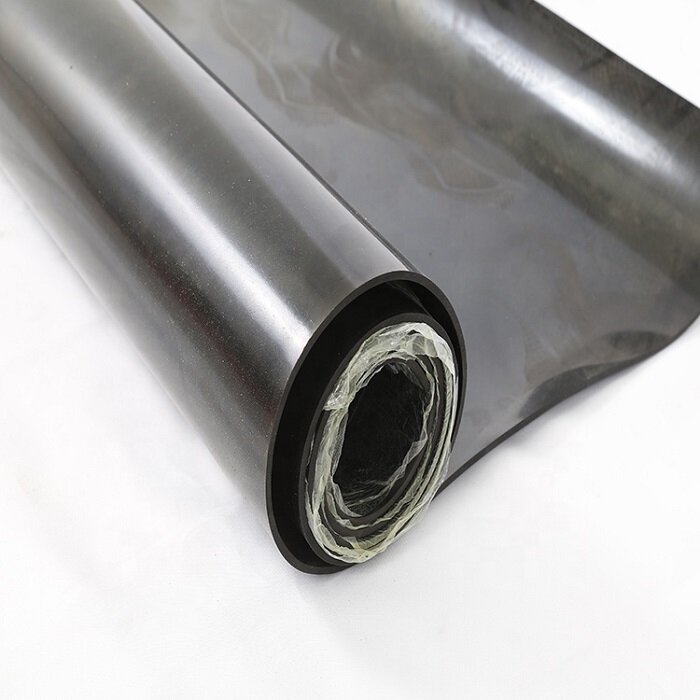

The above information is provided by a rubber sheet manufacturer.

The anti-vibration rubber has a creep phenomenon, which tends to stabilize after 14 days, so the machine tool is required to adjust the level again after 14 days. When a certain tension is maintained, the deformation of the rubber changes with time. After a period of time, the tension is released, and the recovery of the rubber cannot be completed. There will be some residual deformation. This is the creep characteristic of rubber. Any material has certain creep characteristics, but whether it is obvious. Or can it be expressed within the time scale of observation? For example, some small molecular solid materials such as glass, steel, or stone require creep to be observed on a very long time scale. The unvulcanized rubber will show up on a relatively short time scale. Plastic is between rubber and small molecular solid materials.

The above information is provided by a rubber sheet manufacturer.

Related News

Read More >>

What Types of Silicone Sheets Can Be Divided According to the Molding Process?

What Types of Silicone Sheets Can Be Divided According to the Molding Process?

Jul .15.2020

When it comes to the silicone sheet, I believe that many people still feel a little strange now.

What Problems Should Be Paid Attention to When Customizing Rubber Products?

What Problems Should Be Paid Attention to When Customizing Rubber Products?

Jul .06.2020

In recent years, the customized rubber products industry has made great progress.

What Are the Performance Characteristics of Fluoroelastomer Sheet?

What Are the Performance Characteristics of Fluoroelastomer Sheet?

Jul .01.2020

The surface of the fluoroelastomer sheet is shiny, super wide and super long, and has many excellent properties.

Principle of Rubber Shock Mat

Principle of Rubber Shock Mat

Jun .28.2020

The characteristics of anti-vibration rubber mats are both high elasticity and high viscosity.